Contrec 515-DG02

Density Converter

Overview

The 515 DG02 density converter application accepts inputs from density meters, temperature and pressure transmitters and an unassigned input enabling a variable to be connected as an input to the Customer Defined Function (look-up table).

This instrument accepts the analog output from a precision density meter as an accurate representation of the live density.

The converter calculates line (measured) density from the density meter output signal and uses it together with temperature and pressure readings to derive density at reference conditions and calculate specific gravity and other density related variables

Calculations

The line density calculations are based on the measured analog live density signal (generally 4-20mA) coming from accurate density meters.

A variety of calculations are available to suit the nature of the gas and the measurement conditions. The calculations are valid for the vapour

phase of a gas.

Equations Of State:

• Ideal Gas

• Redlich-Kwong

• Soave-Redlich-Kwong

• Peng-Robinson

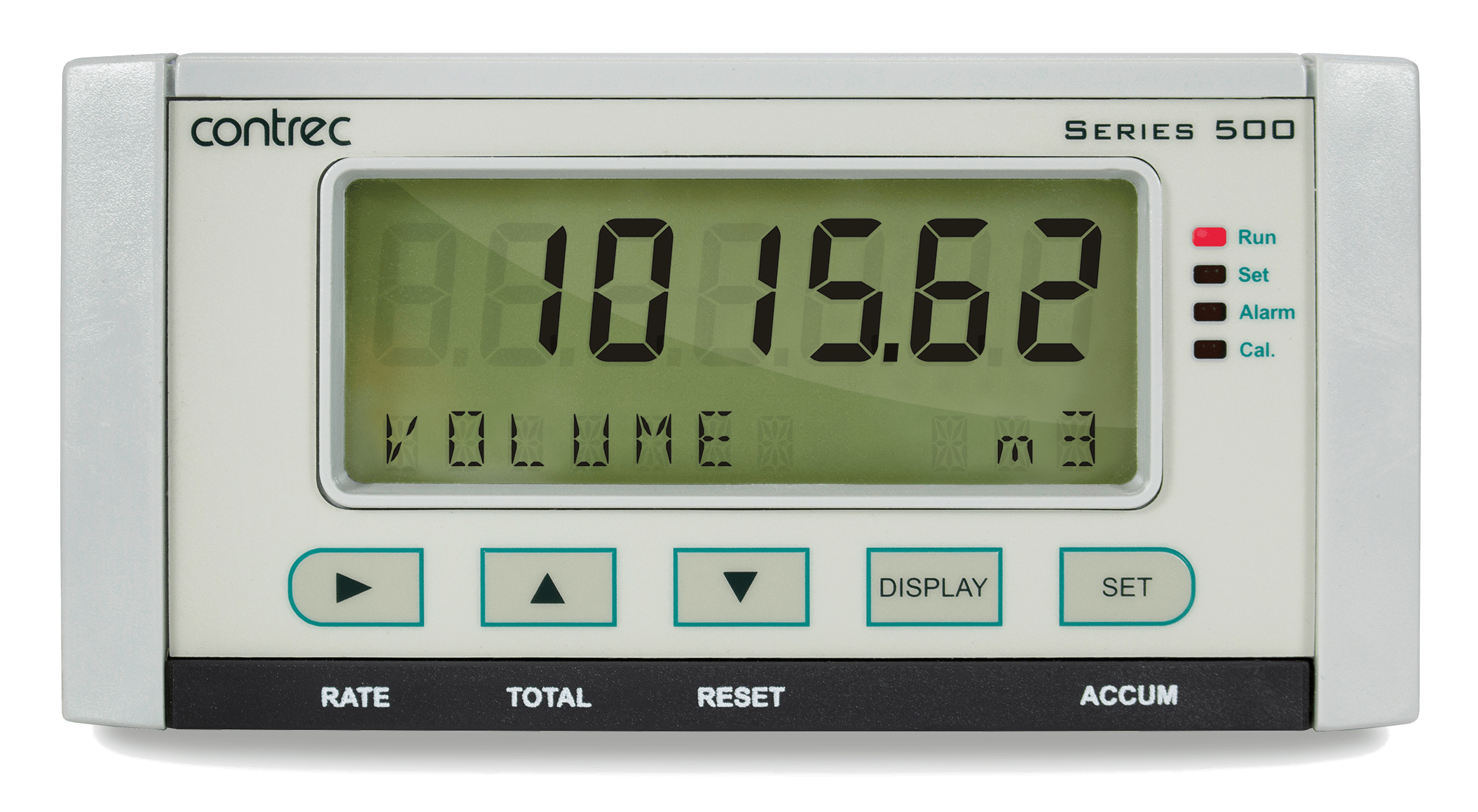

Displayed Information

The front panel display shows the current values of the input variables and the results of the calculations. A list of the variables for this application and their type (total or rate) is shown at the end of this document.

The instrument can be supplied with a real-time clock for data logging of over 1000 entries of the variables as displayed on the main menu.

Communications

There are two communication ports available as follows:

• COM-1 RS-232 port

• COM-2 RS-485 port (optional) or Ethernet (optional)

All types of ports can be used for remote data reading, while RS-232 and RS-485 serial ports can be used for printouts and for uploading and downloading of the application software to the instrument.

Isolated Outputs

The opto-isolated outputs can re-transmit any main menu variable. The variables in this application are output as 4-20 mA signals. One output is standard, a second output is available as an option.

Relay Outputs

The relay alarms can be assigned to any of the main menu variables of a rate type. The alarms can be fully configured including hysteresis. Two relays are standard with an additional two available in the advanced option.

Software Configuration

The instrument can be programmed to suit the particular application needs and the flexible I/O can be assigned as required. Program settings can be changed either via the front panel (depending on assigned access levels) or via

the 500 Series Program Manager (500-PM software).

The instrument stores all set-up parameters and logged data in non-volatile memory with at least 30 years retention.

To see our wide range of flow computers, please click on the link.