Batch/Ratio Controllers

Contrec 214D

Pulse/Frequency Input ATEX/IECEx Batch Controller

Contrec 214D

Pulse/Frequency Input ATEX/IECEx Batch Controller

Contrec 515 -BF01

Frequency Input Batch Controller, Tailored for Volumetric Flow Meters

Contrec 515 -BF01

Frequency Input Batch Controller, Tailored for Volumetric Flow Meters

Contrec 515 – BF02

Analogue Input Batch Controller, Tailored for Volumetric Flow Meters

Contrec 515 – BF02

Analogue Input Batch Controller, Tailored for Volumetric Flow Meters

Contrec 515 – BR01

Frequency Input Batch/Ratio Controller, Tailored for Volumetric Flow Meters

Contrec 515 – BR01

Frequency Input Batch/Ratio Controller, Tailored for Volumetric Flow Meters

Contrec 515 – BR02

Analogue Input Batch/Ratio Controller for Volumetric Flow Meters

Contrec 515 – BR02

Analogue Input Batch/Ratio Controller for Volumetric Flow Meters

Contrec 515 – BR03

Frequency Input Batch/Ratio Controller, Tailored for Mass Flow Meters

Contrec 515 – BR03

Frequency Input Batch/Ratio Controller, Tailored for Mass Flow Meters

Contrec 515 – BR04

Analogue Input Batch/Ratio Controller, Tailored for Mass Flow Meters

Contrec 515 – BR04

Analogue Input Batch/Ratio Controller, Tailored for Mass Flow Meters

Contrec 515 – CR01

Frequency Input Batch Ratio Controller

Contrec 515 – CR01

Frequency Input Batch Ratio Controller

Contrec 515 – CR02

Analogue Input Batch Ratio Controller

Contrec 515 – CR02

Analogue Input Batch Ratio Controller

Contrec 515 – BF03

Frequency Input Batch Controller, Tailored for Mass Flow Meters

Contrec 515 – BF03

Frequency Input Batch Controller, Tailored for Mass Flow Meters

Contrec 515 – BF04

Analogue Input Batch Controller, Tailored for Mass Flow Meters

Contrec 515 – BF04

Analogue Input Batch Controller, Tailored for Mass Flow Meters

Contrec 515 – BS01

Secure Access Batch Controller, Tailored for Inputs from Volumetric Flow Meters

Contrec 515 – BS01

Secure Access Batch Controller, Tailored for Inputs from Volumetric Flow Meters

Contrec 515 – BS03

Secure Dual Stage Batch Controller

Contrec 515 – BS03

Secure Dual Stage Batch Controller

Contrec 515 – BT01

Secure Dual Stage Batch Controller

Contrec 515 – BT01

Secure Dual Stage Batch Controller

Contrec 515-TA02 Dual Cha...

Additive Batch Controller

Contrec 515-TA02 Dual Cha...

Additive Batch Controller

Contrec 434

Frequency Input, Numeric Keyboard Batch Controller

Contrec 434

Frequency Input, Numeric Keyboard Batch Controller

Ratio Controllers

Contrec Ratio Controllers are used for the accurate dispensing and measurement of batch ratios of additives and fluids for a variety of industries from food and beverage production to chemical truck loading.

With over 50,000 instruments installed worldwide Contrec Batch Controllers continue to provide the standard by which our competitors follow. Contrec’s accurate and reliable batch controllers range from the 400 series ideal for Intermediate Bulk Containers (IBC), drum filling and food processing to the 515 series instruments, suitable for more complex batching applications.

Contrec 515 Series Batch Controllers

The 515 Series delivers highly accurate field controllers for the oil and gas industry. It utilises a common, advanced hardware and the functionality is determined by software which is tailored to individual applications. This allows multiple channels and outputs to be configured; allowing applications such as additive injection, ratio blending, temperature and density corrected batching to be easily configured.

For example, our Batch/Ratio Process Controller (BR01) application is a batch ratio controller for delivery of preset quantities at preset ratios using volumetric frequency inputs. Batch control can operate in preset or on-off modes, while flow control can be set to various loop control modes. It offers single or dual stage control as well as no flow, leakage and overflow error detection. Additionally it has a remote run/stop/reset function. As with all the 515 Series batch controllers the BR01 is suitable for use in hazardous areas.

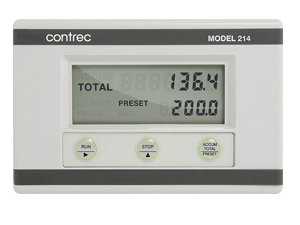

Contrec 400 Series Batch Controllers

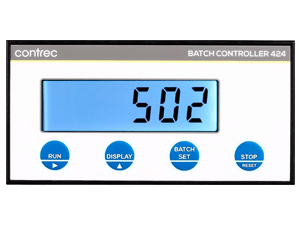

Introduced in 1992, our 400 Series quickly became the industry standard for accurate and reliable flow monitoring and control. In fact, many of those early instruments are still in service today. However, we continue to look at innovative ways to make good flowmeters even better and so our field proven 400 Series has recently received an upgrade. Taking many of the best features of the 400 Series, such as the large LCD displays, rugged reliability and auto run and flow alarm features, we’ve added many more features to the 424 Batch Controller model as standard.

The new 424 Batch Controller will interface to most flowmeters with versions available for pulse outputs. Batch total, flow rate, accumulated total and present value can all be displayed in engineering units on the large LCD display. The instrument comes fitted with both RS232 and RS485 communication outputs to allow it to be monitored and/or controlled remotely from the control room.

All of the batch controllers in the 400 Series can accept either frequency or analogue type flow signals, including signals from differential pressure devices. Incorporating the latest surface mount technology and electronic components the 400 Series range of batch controllers has evolved to meet the ever changing needs of the process industry.

The 430D Batch Controller, for example, is suited to applications where precise measurement and control of variable batch quantities are required. It is extremely flexible and easy to operate allowing for batches to be started, paused, stopped and reset via four operational keys. Batch quantities and calibration parameters are entered via a 12-key numeric keypad.

Contrec has an international reputation for delivering accurate and reliable field controllers. Our instruments continue to prove themselves in the field; years after their installation.

To find out which Contrec Batch Controller is best suited to your application, call us on +44 1422 829944 or email [email protected]