Steam and Condensate Measurement

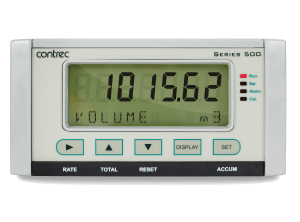

Contrec 515 – SC05

Steam Computer - DP Meter (AGA - 3)

Contrec 515 – SC05

Steam Computer - DP Meter (AGA - 3)

Contrec 515 – SC01 ...

Frequency Input Steam Computer

Contrec 515 – SC01 ...

Frequency Input Steam Computer

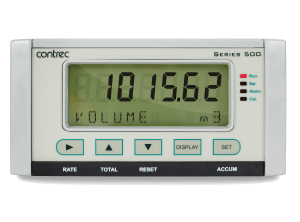

Contrec 515 – SC04

Steam Computer - DP Meter (ISO/Cone)

Contrec 515 – SC04

Steam Computer - DP Meter (ISO/Cone)

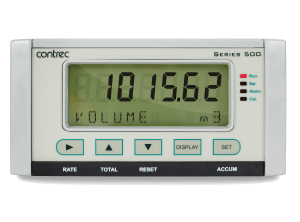

Contrec 515 – SC06

Steam Computer - DP Meter (Volumetric)

Contrec 515 – SC06

Steam Computer - DP Meter (Volumetric)

Contrec 515 – SC02 ...

Analogue Input Steam Computer

Contrec 515 – SC02 ...

Analogue Input Steam Computer

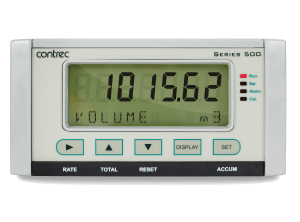

NEW! Contrec 515 – CS02

Condensate and Steam Flow Computer

NEW! Contrec 515 – CS02

Condensate and Steam Flow Computer

Steam Measurement

Steam is used in many different industries in a number of ways. It can be used directly in sterilisation and humidification, or indirectly as a medium for process and space heating, to which it is ideally suited due to its controllability. Food processing, beverage production and brewing all use steam, as do many pharmaceutical and petrochemical processes.

One of its major advantages is its use as a heat transfer medium since a large amount of heat is released when it condenses into water, with very little steam required to carry a large amount of energy. It is also safe, non-toxic and non-flammable, as well as 100% recyclable. However to fully reap the benefits of this recyclable medium measurement is essential. In many countries, governments are offering tax incentives to companies who are embracing the environmental savings that can be delivered by installing accurate steam measurement systems.

In addition, as an energy medium the measurement of steam is in fact the measurement of the flow of energy. It can be used to calculate the energy use in a facility, which can in turn make it easier to identify opportunities to reduce costs and carbon emissions. However, steam is difficult to measure accurately as it is sensitive to changes in temperature and pressure, which change its composition, creating different types of steam. There are three categories of steam: wet, saturated and superheated.

Contrec have a wide range of flow instruments available for steam measurement applications, to see our full range click here.

Wet steam, also referred to as quality steam, contains steam and condensed water. The quality of steam refers to the ratio of steam to water. For example, steam that is 90% steam by weight and 10% water by weight is known as 90% quality steam. The water within this may take the form of fog, cloud or droplets, which in high velocity steam can be as abrasive as sand particles. Wet steam is the most difficult type of steam to measure.

Saturated steam exists at one pressure and corresponding temperature and does not contain any water. It is saturated with heat. If heat is added the temperature of the steam increases above boiling point and if heat is removed condensation occurs and the fluid becomes wet or quality steam. In saturated steam the temperature and pressure are dependent variables and the density can be calculated by measuring just one of these variables.

Superheated steam exists when the temperature of steam is above boiling point. The term ‘degrees of superheat’ refers to how far above the boiling point that temperature is. In superheated steam the temperature and pressure are independent variables and it is necessary to measure both to calculate density to measure mass flow and energy.

There are a number of important design and installation considerations when selecting the most appropriate steam flow meter, including accuracy, repeatability, and turndown ratio, multivariable versus discreet components, as well as installation and maintenance costs.

Accuracy can be affected by the type of installation and the quality of steam. Alongside accuracy, repeatability, as seen in the consistency of results, is also important but may suffer due to the long-term erosive effects of steam flow as parts become worn.

All steam meters have stipulated maximum and minimum flow limits beyond which their accuracy and /or repeatability will deteriorate. The turndown ratio is a means of describing the span of flow rates over which a meter will work within given tolerances of accuracy and repeatability. This can also be referred to as effective range or rangeability.

To calculate the cumulative heat energy transferred through a pipe it is necessary to determine the flow of steam through the pipe over a given time, as well as the pressure and temperature. This can be done through an integrated meter or through the use of discreet components feeding their data to a flow computer. The type of application will determine the type of flow measurement system to be selected.

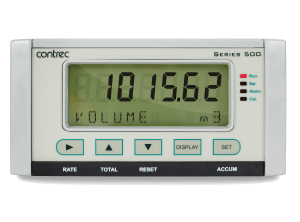

By using the latest technology it is possible to measure steam mass and steam energy, as well as temperature and pressure. For example, Contrec’s 515 SC04 steam flow computer measures the volume, mass and energy content of steam by using single or stacked differential pressure flow inputs in conjunction with temperature and pressure inputs.

Flow is calculated according to equations for ISO 5167 or V-Cone meters and accurately accounts for thermal expansion effects. The energy calculations are based on the IAPWS Industrial Formulation (1997) for the thermodynamic properties of steam. Pressure and temperature values are used to determine the specific volume and enthalpy. It also calculates the isentropic exponent and absolute viscosity, which are required for the differential pressure flow-rate calculations.

Contrec’s 515 SC04 has a selection of various modes that make it suitable for many steam applications, allowing businesses to monitor their steam usage, and in so doing their energy consumption.

Condensate Measurement

Condensate water is widely used in industry to improve energy footprints, reduce waste and minimise costs in industrial steam using facilities. Condensate is typically high temperature water, which has been through a heating process (often referred to as latent heat), an example being a steam boiler where water is heated until it becomes saturated or superheated steam. That steam is then used as a source of energy for many processes including building heating, precise temperature control of food and beverage production, industrial laundry facilities etc. Once the steam has been used for it’s primary purpose, it then condenses back into water and in efficient boiler systems, that condensate is then returned to the boiler. The condensate at this point is still carrying a lot of energy (known as sensible heat) which helps reduce the amount of additional energy the boiler needs to provide in order to produce further steam, it also reduces the amount of ‘make up’ water needed.

In many countries, governments will offer tax incentives to companies to improve their plant performance. Steam metering is already widely used in industry to ensure boiler efficiency, departmentalise costs and improve process performance. Bringing condensate energy into this equation allows the total net energy of the plant to be accurately measured and recorded.

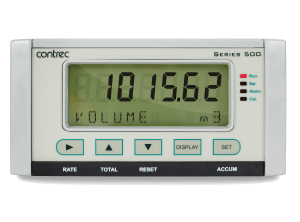

Contrec’s 515-CS range of flow computers accept inputs for steam flow, temperature and pressure, but will also then measure the temperature of the returning condensate water, to calculate net volume, mass and energy of the steam and condensate.

For more information on Contrec's flow computers for steam and condensate measurement click here or email us at [email protected]