For more information on other products please click below.

Back to Product Index Back to Product Index Back to Product Index

Frequency Input Batch/Ratio Controller, Tailored for Volumetric Flow Meters

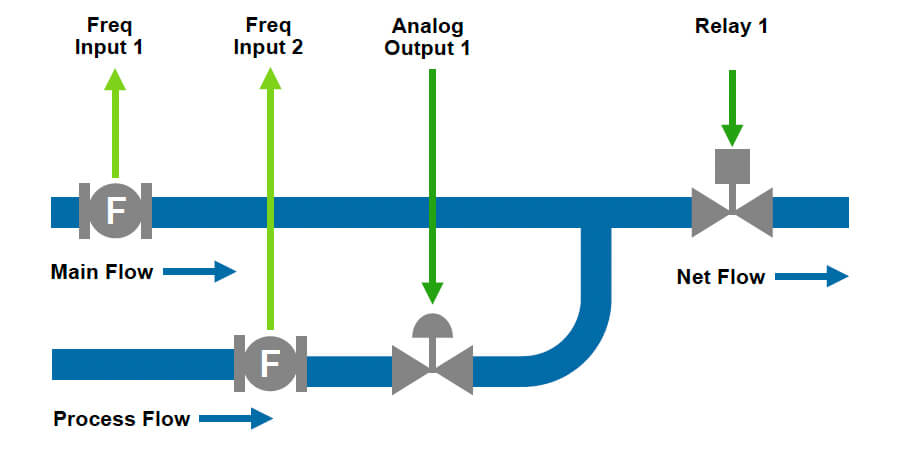

The 515-BR01 application is a batching process controller for delivery of preset quantities at preset ratios using volumetric frequency inputs. Batch control can operate in preset or on-off modes, while flow control can be set to various loop control modes.

The process controller provides the operator with clear local readout including flowrate deviation and can be controlled via communications in more automated systems. There is quick access to commonly used preset values directly from the front panel if access has been authorised.

The PI control of the process flow is via a 4-20mA proportional valve or pump controller. It has integral wind- up protection, a deadband, output hold and ramp time that can be programmed to reduce wear on valves and actuators and provide for bumpless operation.

Calculations

There are three types of control modes in which the process flow is dependent on the main flow. These are RATIO, BLEND-1 and BLEND-2 modes where the relationship between the flows are as follows:

• Ratio Control Mode: the process flow is a ratio of the main flow (0 to 400% range).

• Pflow Ratio% = —————- × 100 Mflow

Blend Control Modes.

These modes cater for blending points before and after the main flowmeter. The process flow is a ratio of the net (combined) flow (0 to 80% range):

• Pflow Ratio% = —————- × 100 Netflow

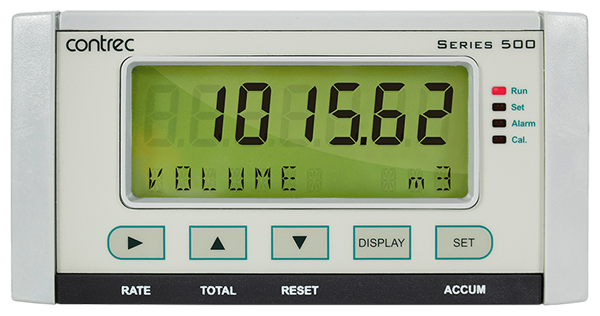

Displayed Information

The front panel display shows the current values of the input variables and the results of the calculations. A list of the variables for this application and their type (total or rate) is shown at the end of this document.

The instrument can be supplied with a real-time clock for storage of up to 1000 transactions with time and date stamps.

Communications

There are two communication ports available as follows:

• COM-1 RS-232 port

• COM-2 RS-485 port (optional) or Ethernet (optional)

The ports are available for remote data reading, printouts and for initial application loading of the instrument.

Isolated Outputs

The opto-isolated outputs can be configured to retransmit any main menu variable or provide various error/control signals (flow error, pump control, end-of-batch, etc.). One output is standard, a second output is available as an option.

Relay Outputs

The relay outputs 1 and 2 are used to control the flow of product for each delivery. These contacts are normally open and can be used to drive external relays, valves,pump circuits etc. The advanced option provides another two relays that can be used as fully programmable alarms for any rate type variable.

Software Configuration

The instrument can be programmed to suit the particular application needs and the flexible I/O can be assigned as required. Program settings can be changed either via the front panel (depending on assigned access levels) or via the 500 Series Program Manager (500-PM software).

The instrument stores all set-up parameters, totals and logged data in non-volatile memory with at least 30 years retention.

Features

Tailored for volumetric frequency flow input

Tailored for volumetric frequency flow input  Single or Dual stage control

Single or Dual stage control  Preset or manual On-Off modes

Preset or manual On-Off modes  Easy access to batch and flow rate presets

Easy access to batch and flow rate presets  No-flow, leakage and overflow error detectio

No-flow, leakage and overflow error detectio  Remote RUN/STOP/RESET

Remote RUN/STOP/RESET  Allows for permissive with prompt

Allows for permissive with prompt  Uses PI Loop Control

Uses PI Loop Control  Allows for non-linear correction

Allows for non-linear correction  Storage of 1000 transactions with time and date stamp

Storage of 1000 transactions with time and date stamp  Selection of second language and user tags

Selection of second language and user tags  Selectable protocols on serial ports including Modbus RTU and Printer output

Selectable protocols on serial ports including Modbus RTU and Printer output  Backlit display with LCD backup

Backlit display with LCD backup Typical plant diagram

Downloads

Related Accessories

Software – Program Manager (Download)

Software – DataMod Tool

IP65 – Stainless Steel (Custom)

IP66 – Weatherproof Enclosure

PR-00 – Thermal Panel Printer

PR-02 – Desktop 24VDC or 240VAC

PR-01 – Roll Printer (Panel Mount Impact)

PR-03 – Desktop 240VAC 80 Col

PR-04 – Thermal Ticket Printer