For more information on other products please click below.

Back to Product Index Back to Product Index Back to Product Index

Frequency Input Net Oil Flow Computer, Tailored for Mass Flow Meters

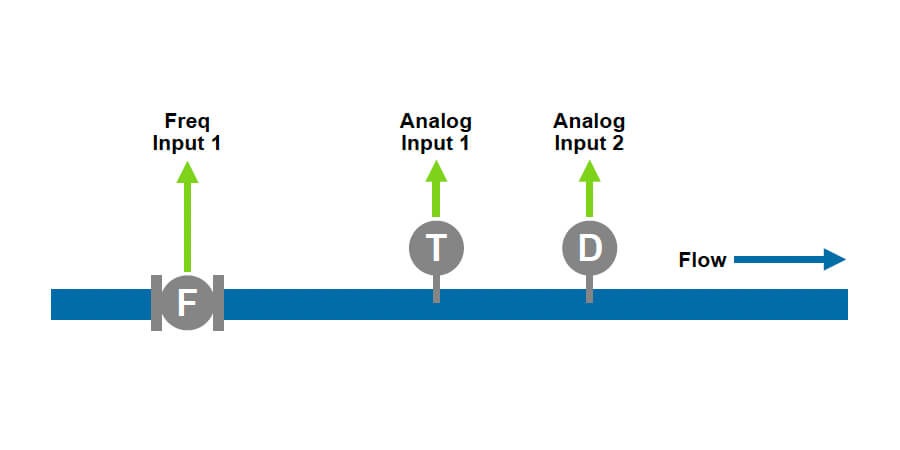

The 515-FN01 Net Oil Computer calculates the net oil content in petroleum production fluids containing water. The net oil volume is corrected to a reference temperature according to ASTM D1250-04. The instrument uses the frequency signal from a mass flowmeter along with temperature and density analog inputs.

Reference densities for the oil and water are used in conjunction with live density and temperature values to determine the water cut.

The Contrec 515-FN01 Net Oil Computer is compatible with a wide range of flowmeter frequency outputs, including millivolt signals, reed switches, Namur proximity switches and pulse trains via its smart front-panel program selection.

Calculations

The mass total and flowrate are derived from accurately measured frequency and the number of received pulses:

• mass = pulses/k-factor

• mass flow = frequency/k-factor

The oil volume correction calculations are based on the ASTM D1250-04 standard for the following products:

• Crude Oils

• Lube Oils

• Refined Products

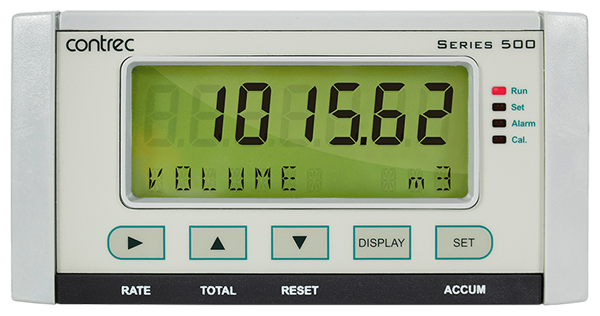

Displayed Information

The front panel display shows the current values of the input variables and the results of the calculations. A list of the variables for this application and their type (total or rate) is shown at the end of this document.The instrument can be supplied with a real-time clock for data logging of over 1000 entries of the variables as displayed on the main menu.

Communications

There are two communication ports available as follows:

• COM-1 RS-232 port

• COM-2 RS-485 port (optional) or Ethernet (optional)

All types of ports can be used for remote data reading, while RS-232 and RS-485 serial ports can be used for printouts and for uploading and downloading of the application software to the instrument.

Isolated Outputs

The opto-isolated outputs can re-transmit any main menu variable. The type of output is determined by the nature of the assigned variable. Totals are output as pulses and rates are output as 4-20 mA signals. One output is standard, a second output is available as an option.

Relay Outputs

The relay alarms can be assigned to any of the main menu variables of a rate type. The alarms can be fully configured including hysteresis. Two relays are standard with two additional relays available as an option.

Software Configuration

The instrument can be programmed to suit the particular application needs and the flexible I/O can be assigned as required. Program settings can be changed either via the front panel (depending on assigned access levels) or viathe 500 Series Program Manager (500-PM software).

Features

Calculates the Net Oil content in petroleum production fluids containing water

Calculates the Net Oil content in petroleum production fluids containing water  Volume correction according to ASTM D1250-04

Volume correction according to ASTM D1250-04  Uses temperature and density inputs for volume correction

Uses temperature and density inputs for volume correction  Allows for non-linear correction

Allows for non-linear correction  Selection of second language and user tags

Selection of second language and user tags  RTC logging with over 1000 entries

RTC logging with over 1000 entries  Infra-red communications port on front panel

Infra-red communications port on front panel  Pulse width and scaling of pulse output

Pulse width and scaling of pulse output  4-20mA retransmission

4-20mA retransmission  Selectable protocols on serial ports including Modbus RTU and Printer output

Selectable protocols on serial ports including Modbus RTU and Printer output  Front panel adjustment of 8-24V DC output voltage

Front panel adjustment of 8-24V DC output voltage  Backlit Display

Backlit Display  LCD Backup

LCD Backup Typical plant diagram

Downloads

Related Accessories

Software – Program Manager (Download)

Software – DataMod Tool

IP65 – Stainless Steel (Custom)

IP66 – Weatherproof Enclosure

PR-00 – Thermal Panel Printer

PR-01 – Roll Printer (Panel Mount Impact)

PR-02 – Desktop 24VDC or 240VAC

PR-03 – Desktop 240VAC 80 Col

PR-04 – Thermal Ticket Printer