For more information on other products please click below.

Back to Product Index Back to Product Index Back to Product Index

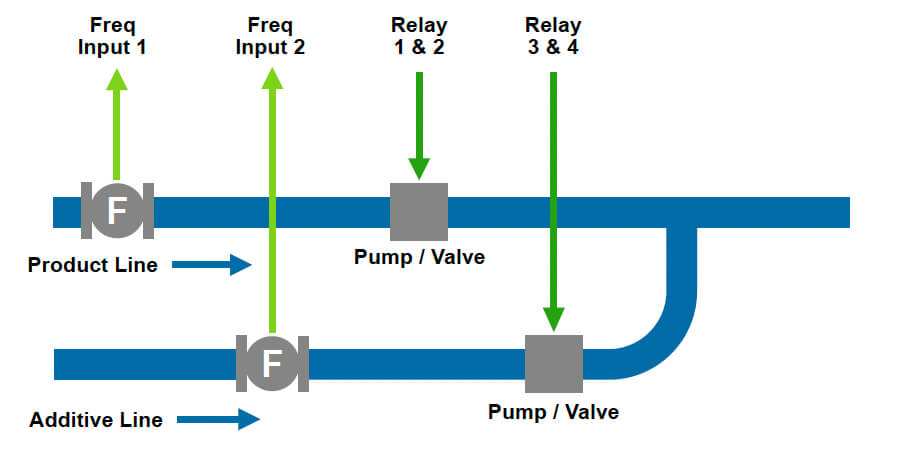

The 515-BA01 application is a batch/additive controller designed to be a standalone unit capable of controlling a batch and the injection of an additive into a main product line during a delivery. Both the main and additive inputs are for volumetric frequency flowmeters.

Batch control can operate in preset or on-off modes. In PRESET mode the 515-BA01 is responsible with providing the dual stage batch control of a main line product as well as controlling the dosing of an additive product into the main product. In UNLOAD/PACING mode the unit operates in conjunction with an external load or batch controller by monitoring a main line flow signal and is responsible for the accurate dosing of the additive.

An intelligent additive dosing algorithm and trimming has been designed in the 515-BA01 which simplifies the programming required and ensures the additive dosing remains within specification. Dosing is primarily based on the target dosing PPM and the nominal additive

flowrate with the choice of time or quantity based intervals.

Calculations

The total and flowrate are derived from accurately measured frequency and the number of received pulses.

volume = pulses / k-factor

volume flow = frequency / k-factor

Automatic overrun compensation calculates the new valve closure point to ensure correct delivery by averaging the overrun amount from

the last three complete batches.

The overrun compensation value is valid for a new preset value provided the stored overrun is less than 20% of the new preset.

Displayed Information

The front panel display shows the current values of the input variables and the results of the calculations. A list of the variables for this application and their type (total or rate) is shown at the end of this document.

The instrument can be supplied with a real-time clock for storage of up to 1000 transactions with time and date stamps.

Communications

There are two communication ports available as follows:

• COM-1 RS-232 port

• COM-2 RS-485 port (optional) or Ethernet (optional)

The ports are available for remote data reading, printouts and for initial application loading of the instrument.

Isolated Outputs

The opto-isolated outputs can be configured to retransmit any main menu variable or provide various error/control signals (flow error, pump control, end-of-batch, etc.). One output is standard, a second output is available as an option.

Relay Outputs

The relay outputs 1 and 2 are used to control the flow of product for each delivery. These contacts are normally open and can be used to drive external relays, valves, pump circuits etc. The advanced option provides another two relays that can be used as fully programmable alarms for any rate type variable.

Software Configuration

The instrument can be programmed to suit the particular application needs and the flexible I/O can be assigned as required. Program settings can be changed either via the front panel (depending on assigned access levels) or viathe 500 Series Program Manager (500-PM software).

The instrument stores all set-up parameters, totals and logged data in non-volatile memory with at least 30 years retention.

Features

Accurately controls the additive into a batch or loading process

Accurately controls the additive into a batch or loading process  Volumetric frequency flow on product and additive lines

Volumetric frequency flow on product and additive lines  Product line has 2 stage valve control, Additive line has pump and valve control

Product line has 2 stage valve control, Additive line has pump and valve control  Batch mode can be PACING, UNLOAD, PRESET, or ON-OFF

Batch mode can be PACING, UNLOAD, PRESET, or ON-OFF  Dosing can be fixed quantity or ratio controlled

Dosing can be fixed quantity or ratio controlled  Additive Target Ratio is entered in PPM in the range of 0 – 99999 (0 to 10%)

Additive Target Ratio is entered in PPM in the range of 0 – 99999 (0 to 10%)  Special flush and trim algorithms included

Special flush and trim algorithms included  Permissive inputs available for product and additive lines

Permissive inputs available for product and additive lines  Test input available for calibration and commissioning

Test input available for calibration and commissioning  Allows for non-linear correction of flow input

Allows for non-linear correction of flow input  Storage of 1000 transactions with time and date stamp

Storage of 1000 transactions with time and date stamp  Selection of Detail or Basic main menu to suit operator and application

Selection of Detail or Basic main menu to suit operator and application  Available protocols on communication ports including Printers, Modbus RTU & TCP/IP

Available protocols on communication ports including Printers, Modbus RTU & TCP/IP Typical plant diagram

Downloads

Related Accessories

Software – Program Manager (Download)

Software – DataMod Tool

IP65 – Stainless Steel (Custom)

IP66 – Weatherproof Enclosure

PR-00 – Thermal Panel Printer

PR-01 – Roll Printer (Panel Mount Impact)

PR-02 – Desktop 24VDC or 240VAC

PR-03 – Desktop 240VAC 80 Col

PR-04 – Thermal Ticket Printer